Research

Facilities

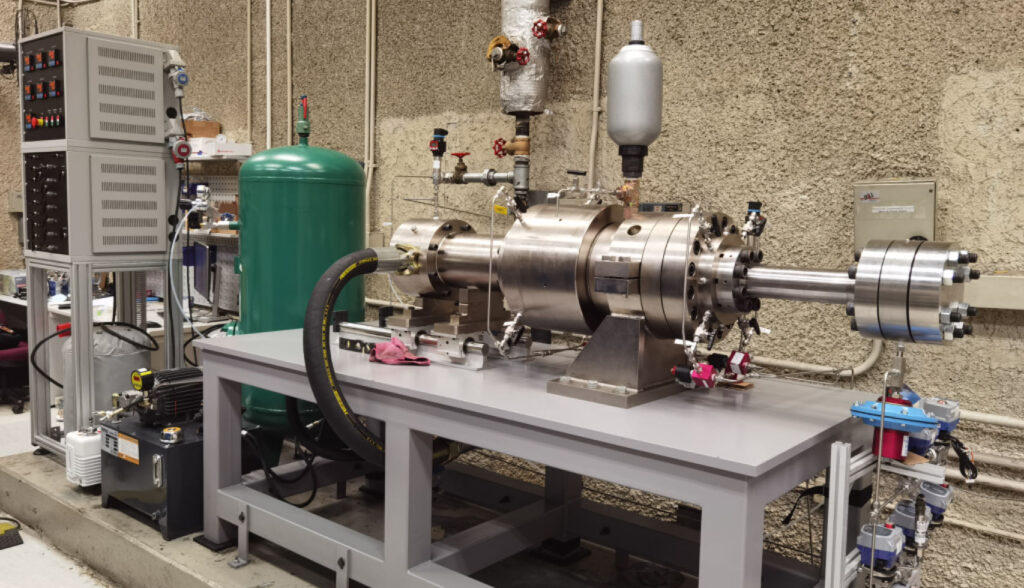

UHP-RCM & HRR-Tof-MS Platform

The first-of-its-kind platform couples a customized Ultra-High-Pressure Rapid Compression Machine and a High-Repetition-Rate Time-of-Flight Mass Spectrometry, enabling characterization of fuel pyrolysis, oxidation and autoignion at 600–1400 K, 1–1000 bar, various equivalence ratios and diluent ratios, which is ideal to study atmospheric to supercritical combustion chemistry.

In addition, heat release rate can be robustly extracted from recorded pressure-time histories.

This platform can be used to study the combustion characteristics of gaseous, liquid and solid fuels at conditions representative of heavy-duty, gas turbine and rocket engines.

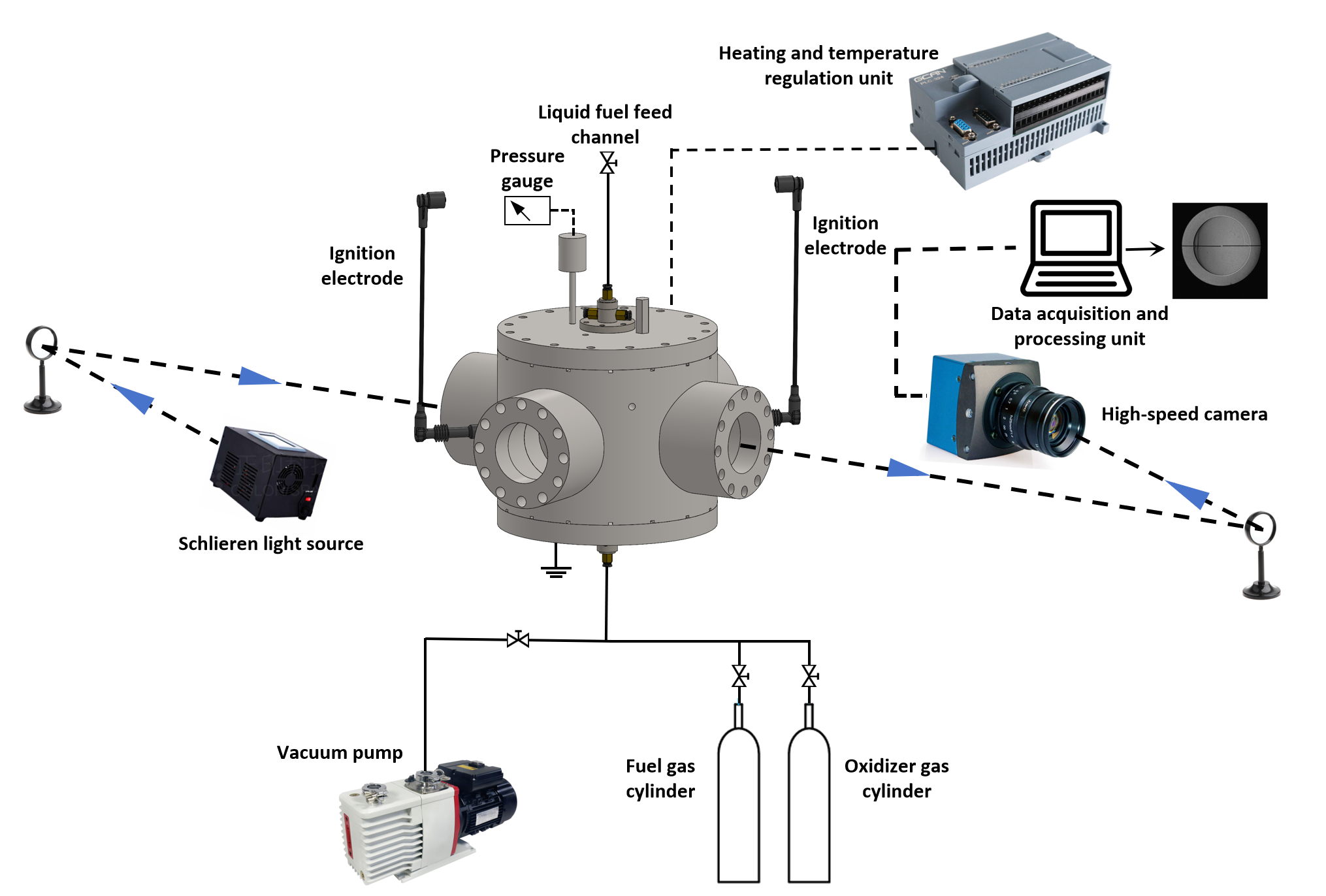

The High-Pressure Constant Volume Combustion Chamber & Laser-Induced High-Speed Imaging

The platform integrates a CVCC, a mixing and feeding system, a Schlieren imaging system, and a laser imaging system (2 YAG lasers & 1 Dye laser) coupled with 3 ICCD cameras.

The platform can be used to characterize laminar premixed and non-premixed flames under pressures up to 300 bar for gaseous and liquid fuels, from which laminar burning velocity, extinction strain rate, spatially resolved radical/intermediate distribution, and soot formation can be quantified.

The platform is designed for studying transcritical and supercritical laminar flame dynamics.

High-Pressure Flow Reactor

& Micro-GC Platform

The platform combines a fused silica flow reactor, a fuel-feeding system, a gas sampling system, and a Micro-GC.

The flow reactor is able to generate a fully premixed homogeneous mixture with well-controlled temperature. The fuel-feeding system can supply different gaseous and liquid fuels into the reactor inlet at various flow rates. The Micro-GC can detect and analyze the concentration of different species from the extracted samples through a sampler that can move along the tube.

With this platform, pyrolysis and oxidation of gaseous and liquid fuels can be characterized at various temperatures and residence times, and pressures up to 300 bar.

Real-Time

High-Speed Imaging Platform

The high-speed imaging platform combines two high-speed cameras, a Photron SA-Z high-speed camera mounted with a Questar QM-100 lens and a Chronos 2.1 high-speed camera from Kron Technologies equipped with a TCLO lens.

With the platform, droplet impact dynamics including coalescence, bouncing, partial coalescence, reflexive separation, etc., can be recorded at up to 40000 fps with a spatial resolution of 1024×512.

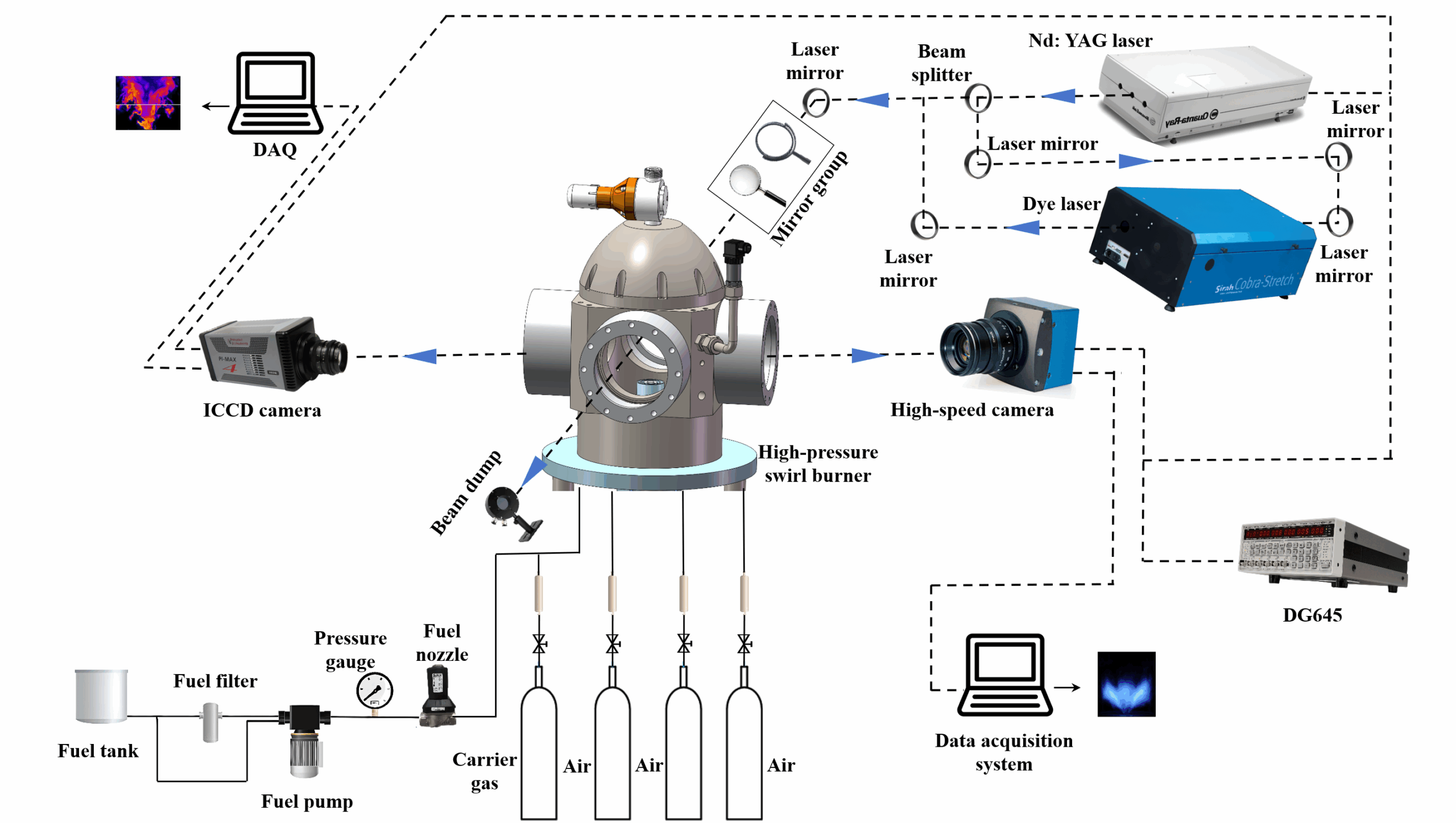

High-Pressure Turbulent Swirl Burner

& Laser-Induced High-Speed Imaging System

The platform combines a high-pressure chamber, a swirl burner with variable swirling ratios, a fuel-feeding system, a laser-induced imaging system, and a Micro-GC.

The laser system includes a PRO-290-10 Primary Nd: YAG Laser, a INDI-40-10-HG Secondary Nd: YAG Laser, and a PSCAN-LG-24-EG Tunable DYE Laser. The imaging system includes a “Princeton Instruments” PM4-1024I-SB-FG-18-P46 Intensified CCD Camera and an “Andor” iStar DH334T Intensified CCD Camera.

The platform enables PLIF and LII detection, which can be used to characterize the flame dynamics and soot/PAH characteristics for gaseous and liquid fuels at 1–200 bar.

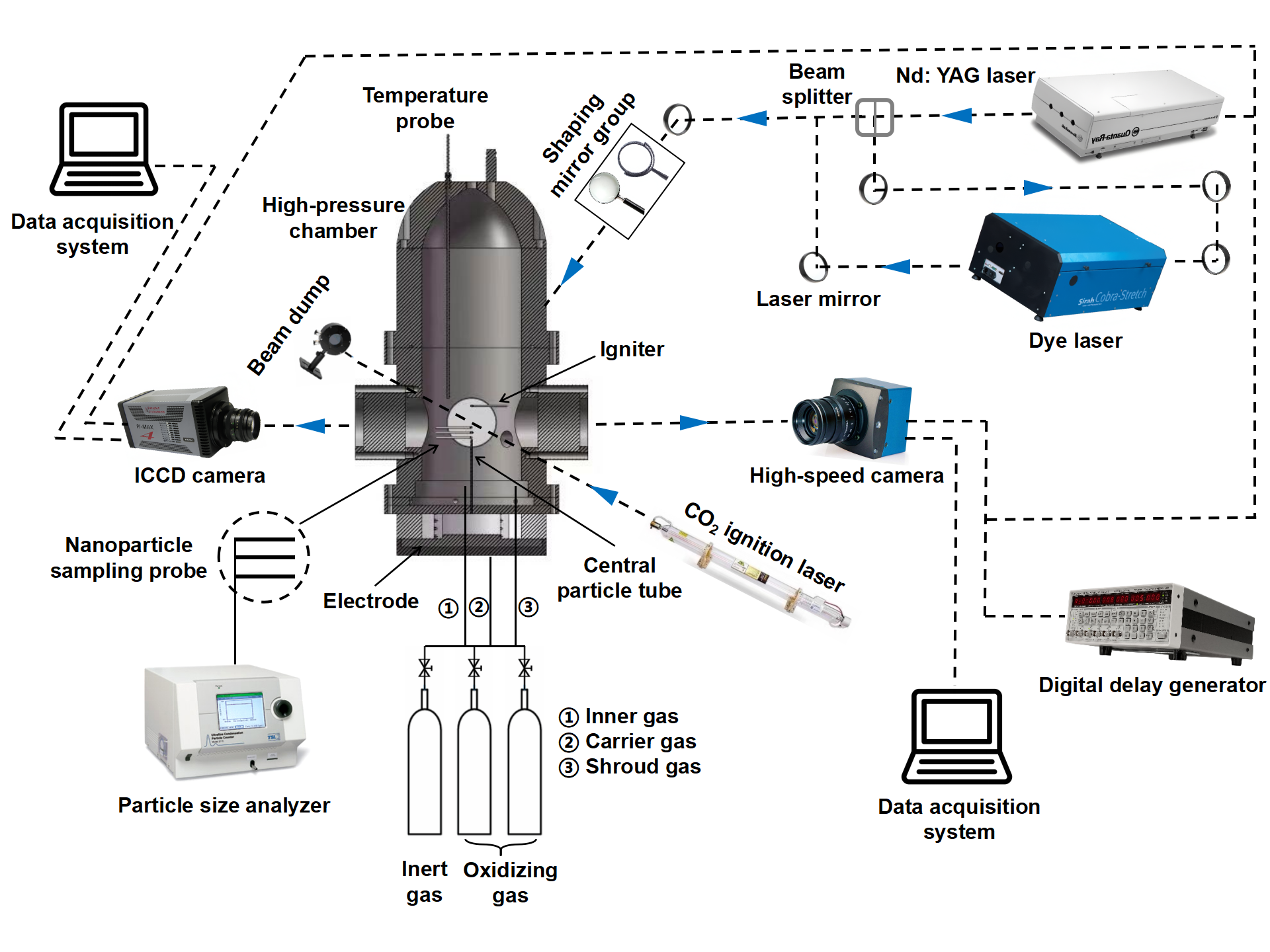

High-Pressure Particle Burner

& Laser-Induced High-Speed Imaging System

The platform combines a high-pressure chamber, a particle burner for micro- and milli-sized particles, a particle ignition system, a micro imaging system, a laser-induced imaging system, and an online sampling system.

The high-pressure chamber supports particle combustion characterization at pressures up to 200 bar. The particle burner enables the measurements for both micro-sized and milli-sized particles with two different feeding mechanisms. The platform is equipped with two sets of ignition systems (a CO2 laser ignition system and a flat flame burner ignition system). The laser imaging system enables the characterization of spatially resolved concentration distribution in the radial direction surrounding the particle. The online sampling system can analyze the particle distribution in the smoke formed during particle combustion.

This platform is tailored for studying metal/biomass/waste combustion fundamentals, microexplosion, interphase dynamics, interfacial chemistry (gas-liquid, gas-solid, liquid-solid) under extreme conditions.

Super-Computing Platform

The platform includes a PILOT Supercomputing Platform (10 nodes, 4 TB memory) and a BUDA Supercomputing Platform (60 nodes, 12 TB memory), with over 3000 CPU cores and 20 GPU cards.

With the platform, high-accuracy quantum chemistry calculations, molecular dynamics calculations, quantum mechanics calculations can be efficiently conducted.